LIMITED OFFER: FAST WITH FREE 2-DAY ✈️ SHIPPING ON ALL ORDERS!

Technology

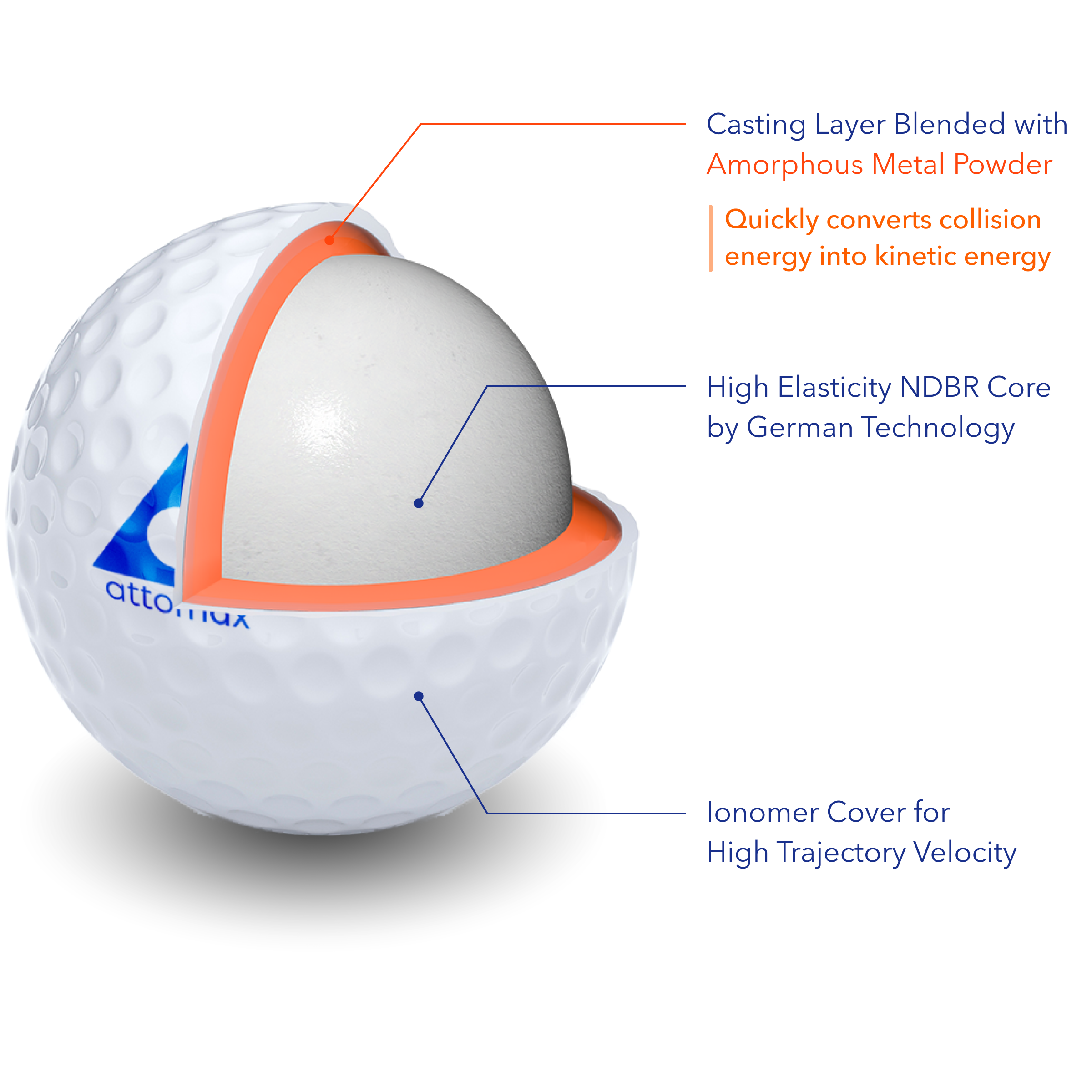

We use an amorphous metal alloy powder for our golf balls

High-density, Hyper-elastic with Amorphous Metal Powder increases maximum distance and speed. In a certification test conducted using a WRC-approved robot swinger, the Attomax golf ball flew 13 to 18 meters (15 to 20 yards) more than the 13 types of golf balls from 10 other brands. Certified its Attomax golf ball as the world’s longest golf ball.

Amorphous metal powder

We developed the world's first high-density golf ball using amorphous metal alloy. Dr. Paul Kim from Caltech researched our technology amorphous metal powder, and currently, Dr. Paul Kim is working with Attomax. Mr. JG Park, who designed our golf balls, has 25+ years of experience in the golf industry in South Korea and Japan. We are only a handful of companies worldwide that succeeded in volume production of the amorphous metal alloy. We have put Paul and JG's names on our ball.

What is the Amorphous Metal?

Amorphous metals are non-crystalline, and have a glass-like structure. But unlike typical glasses, such as window glass, which are typically electrical insulators, amorphous metals have good electrical conductivity and can show metallic luster.

An amorphous metal is a solid metallic alloy material that exhibits an unusual atomic-scale structure compared to all other metals. Amorphous metals are produced by several differing procedures, all of which are complex and require specialized equipment and trained personnel. The first successful production of an amorphous metal (also known as metallic glass) occurred at Caltech in 1960. The positive quality is its high coefficient of restitution (COR). This measure of the “restitution” of a collision between two objects and how much kinetic energy remains for the objects to rebound makes the material ideal for manufacturing thin-faced golf club heads and golf balls.

Amorphous metal alloy

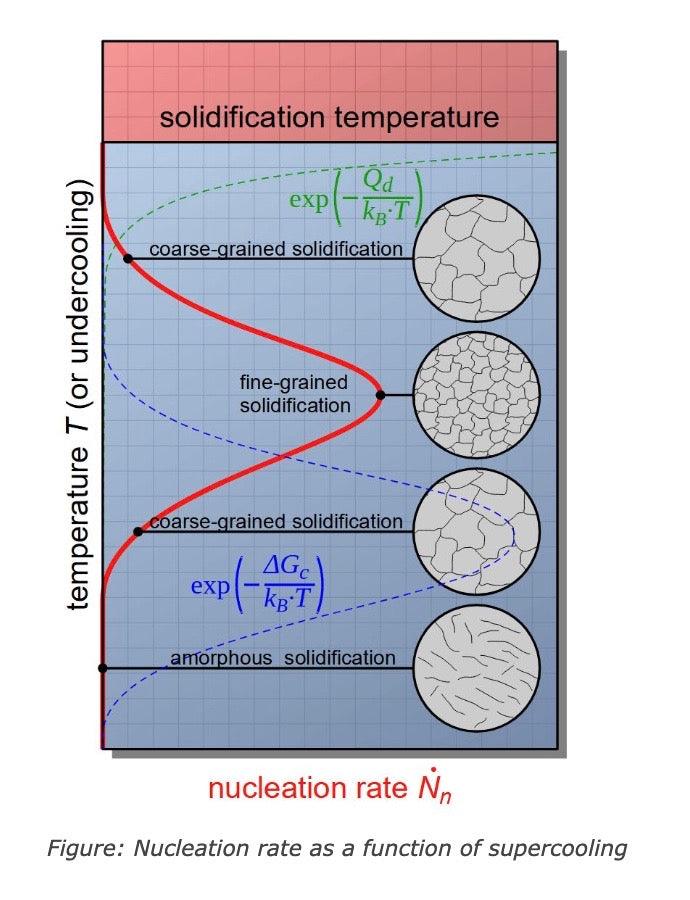

The amorphous structure exhibits new properties different from the crystalline structure, such as high elasticity, strength, and strong corrosion resistance. Crystal structure alloys have boundaries between crystal structures called grain boundaries, and grain boundaries are mechanism factors for corrosion and deformation. In contrast, amorphous forms do not have such grain boundaries, so they are structurally flawless and have unique characteristics.

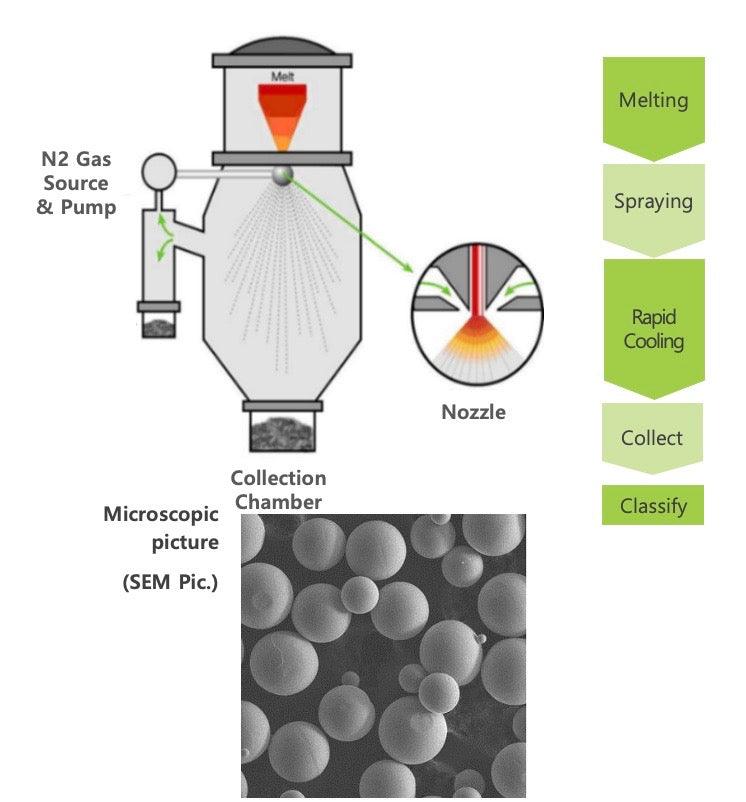

Our gas atomization process

Formed by cooling liquid metal rapidly, which prevents crystallization.

Nucleation rate as a function of supercooling

(Image source: tec-science.com)

Quick links

Contact

611 Gateway Blvd, Ste 120

South San Francisco, CA 94080

About us

We developed the world's first high-density golf ball using amorphous metal alloy.